My 10BBL Brew Day in Pictures

Posted: Mon Sep 08, 2014 11:58 am

A word of warning - this is a very long post, so you may want to grab some popcorn (or better yet, some homebrew)!

Last Friday, September 5, 2014, I went down to Mickey Finn's Brewery in Libertyville, IL to brew a 10 barrel (300 gallons) batch of my Aurora Baltic Porter. I invited a friend (who also brews) to come with me, and I'm glad I did - more about that in a minute! We showed up around 9 am, met Brewmaster Greg Browne, and got a tour of the brewery. They have a 10 BBL brewhouse and 20 BBL conicals, so they can brew double batches. Most of the equipment is very similar to what we use as homebrewers; this is not a "push button" operation:

Mash Tun (insulated, no heat source):

Boil Kettle (direct fired):

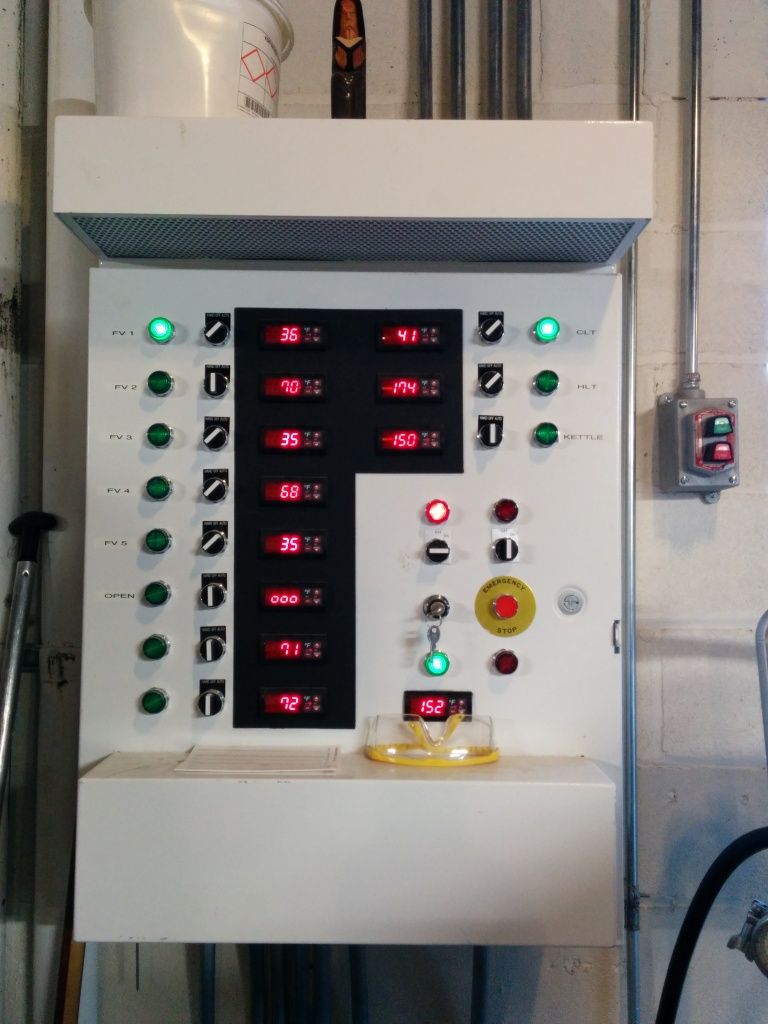

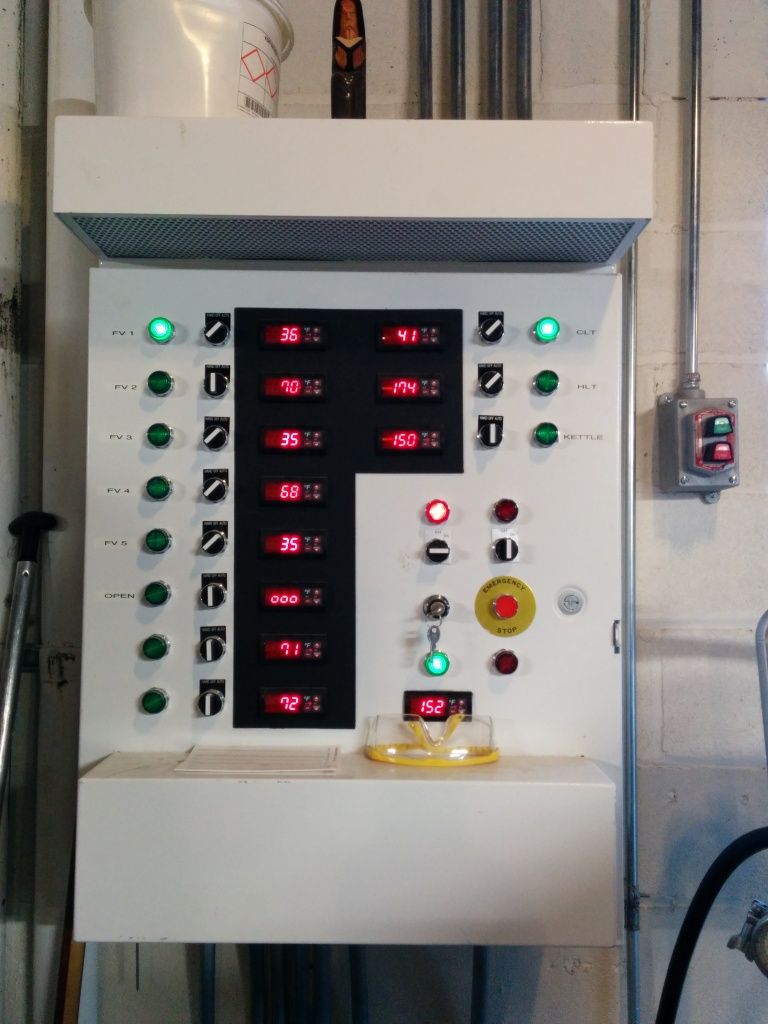

Control Panel:

Heat Exchanger, Pumps, and Manifold Panel:

Conical Fermenters:

Grain Mill and Grist Case:

Bright/Serving Tanks:

Draft System:

Not pictured (apparently I forgot to take a picture) are Hot and Cold Liquor Tanks.

After the tour, we got down to business! Their grist case only holds about 800 pounds of grain, and the bill for this recipe was over 1000 pounds, so I had to dump several 50 pound bags of milled grain directly into the mash tun with a bit of hot water before we could use the grain conveyor:

Just like at home, you got to mix the mash. And you can't mix the mash without proper tools:

Mix, mix, mix...

Once the first few bags were added manually, we turned on the grain conveyor, and the rest of the grist went into the tun, along with hot water. Still had to continue mixing until the tun was full. Just like homebrewers, they mash for a full 60 minutes before moving to the next step. While we were waiting, we grabbed some lunch and tasted some of their beers - all of them were top notch. In the meantime, we heated up some water in the kettle for the mash-out.

Ok, the wait is over, the mash-out water was pumped to the mash tun and we are beginning to vorlauf:

They use a grant during vorlauf and transfer (the blue thing is the heat exchanger):

We grabbed some cups and scooped up some sweet wort... mmm... tasted better than my morning coffee. After the wort ran clear, we started the transfer to the kettle.

After most of the first runnings were pumped to the kettle, we grabbed the sparge arm (here it is in Brewmaster Greg's hands):

And installed it in the mash tun:

We sparged until we collected 11 barrels into the kettle... Now, I'm sure you were all dying to know what my t-shirt said, so here you go:

Anyway, I digress... We turned the kettle on, and while we were waiting for 330 gallons of wort to come to a boil, we had to do the same thing all homebrewers do after the mash... Clean the damn mash tun!

Not quite as easy as dumping a cooler or a grain bag... Well... gotta grab a shovel:

I think we filled 6 or 7 of these trash cans... Well, guess what - the shovel only gets you so far... WE GOTTA GO IN!!! And here's where me bringing a friend really pays off - he loses the coin toss and goes in:

It's cozy in there:

While he's washing the mash tun, we pulled out and washed the false bottom. Luckily, it's in three pieces and can be handled pretty easily - here's the middle section going back in:

Alright, the mash tun is clean, and we are coming up to a boil:

Measuring out the first addition - 28 oz of Magnum:

The boil was pretty uneventful, with one more hop addition - 40 oz of Fuggles. After the boil was over, we started the whirlpool... That is, Brewmaster Greg grabbed a paddle and stirred the kettle, just like I used to do in my kitchen:

After the whirlpool, we let everything settle for about half hour, and hooked up hoses and configured the heat exchanger to chill the wort to the fermenter:

Hooked up the inline oxygenation system and started filling the fermenter:

With some wort already in the fermenter, we dumped the yeast in (courtesy of Hofbrauhaus brewery in Rosemont, IL):

As the kettle was draining, I was somewhat surprised to see that the ghetto whirlpool actually worked well - check out the nice trub cone:

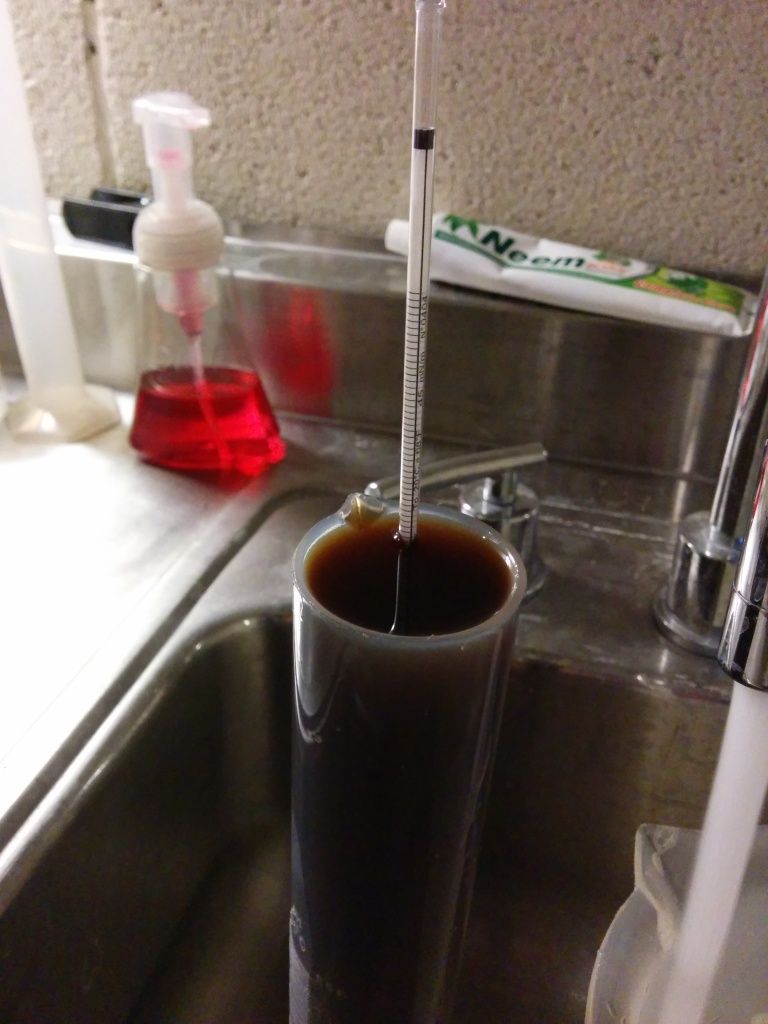

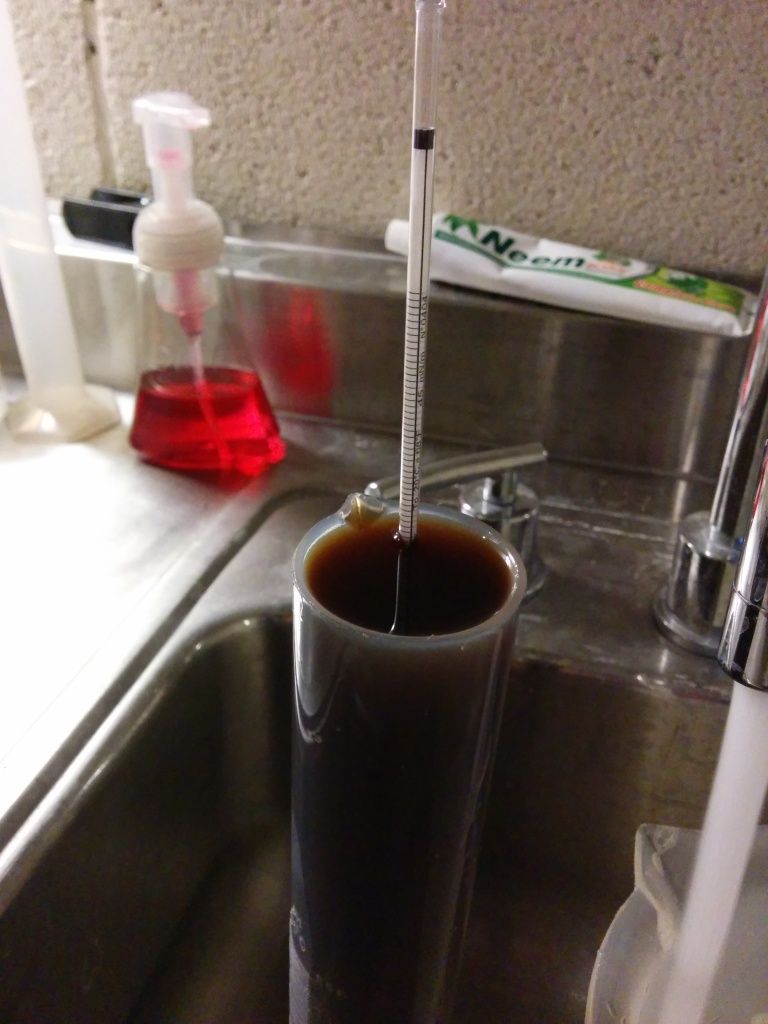

Well, what's left to do? We take a gravity sample (OG: 19.6 Plato)

They graciously allow me to steal some wort straight from the conical (already pitched with lager yeast), as well as another carboy straight from the wort chiller:

Well, the second carboy needed some yeast, and they needed to dump yeast (Americal Ale II) from their White IPA, so they added a squirt to it:

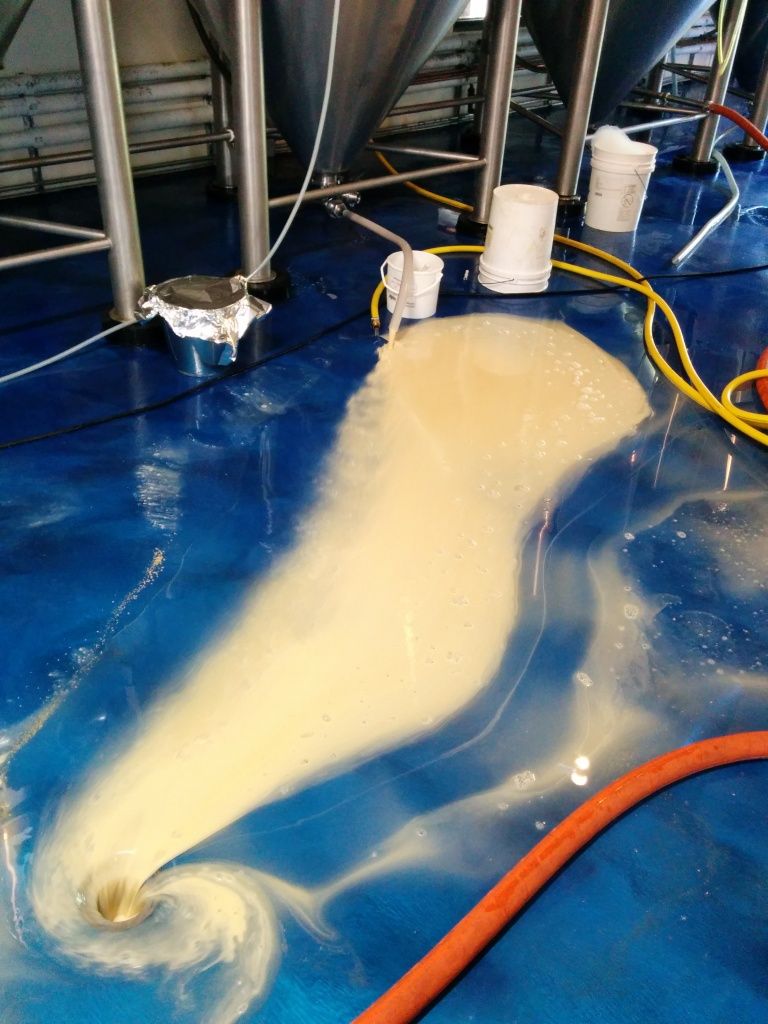

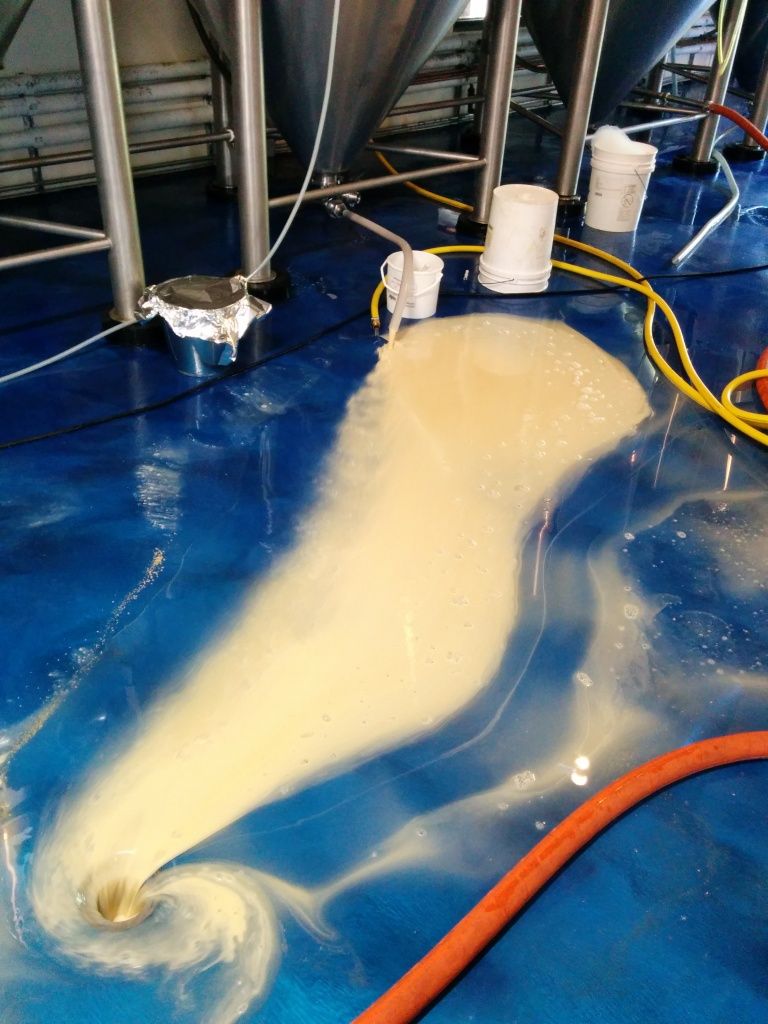

Oh, the humanity! All this yeast down the drain (they saved a bucket - covered with foil on the left - to pitch into another batch):

Well, all that was left was to clean everything, and put the brewery back the way it was when we arrived:

We were done around 4:30 pm. Not bad for a 300 gallon brew day! We finished the day by sitting at the bar and drinking beer - is there any other way?

This was definitely a once in a lifetime opportunity, and I'm glad to have experienced this! In a few weeks, my beer will be on tap at the brewery, and I have my 10 gallon share sitting in my basement, happily bubbling away.

Cheers!

Last Friday, September 5, 2014, I went down to Mickey Finn's Brewery in Libertyville, IL to brew a 10 barrel (300 gallons) batch of my Aurora Baltic Porter. I invited a friend (who also brews) to come with me, and I'm glad I did - more about that in a minute! We showed up around 9 am, met Brewmaster Greg Browne, and got a tour of the brewery. They have a 10 BBL brewhouse and 20 BBL conicals, so they can brew double batches. Most of the equipment is very similar to what we use as homebrewers; this is not a "push button" operation:

Mash Tun (insulated, no heat source):

Boil Kettle (direct fired):

Control Panel:

Heat Exchanger, Pumps, and Manifold Panel:

Conical Fermenters:

Grain Mill and Grist Case:

Bright/Serving Tanks:

Draft System:

Not pictured (apparently I forgot to take a picture) are Hot and Cold Liquor Tanks.

After the tour, we got down to business! Their grist case only holds about 800 pounds of grain, and the bill for this recipe was over 1000 pounds, so I had to dump several 50 pound bags of milled grain directly into the mash tun with a bit of hot water before we could use the grain conveyor:

Just like at home, you got to mix the mash. And you can't mix the mash without proper tools:

Mix, mix, mix...

Once the first few bags were added manually, we turned on the grain conveyor, and the rest of the grist went into the tun, along with hot water. Still had to continue mixing until the tun was full. Just like homebrewers, they mash for a full 60 minutes before moving to the next step. While we were waiting, we grabbed some lunch and tasted some of their beers - all of them were top notch. In the meantime, we heated up some water in the kettle for the mash-out.

Ok, the wait is over, the mash-out water was pumped to the mash tun and we are beginning to vorlauf:

They use a grant during vorlauf and transfer (the blue thing is the heat exchanger):

We grabbed some cups and scooped up some sweet wort... mmm... tasted better than my morning coffee. After the wort ran clear, we started the transfer to the kettle.

After most of the first runnings were pumped to the kettle, we grabbed the sparge arm (here it is in Brewmaster Greg's hands):

And installed it in the mash tun:

We sparged until we collected 11 barrels into the kettle... Now, I'm sure you were all dying to know what my t-shirt said, so here you go:

Anyway, I digress... We turned the kettle on, and while we were waiting for 330 gallons of wort to come to a boil, we had to do the same thing all homebrewers do after the mash... Clean the damn mash tun!

Not quite as easy as dumping a cooler or a grain bag... Well... gotta grab a shovel:

I think we filled 6 or 7 of these trash cans... Well, guess what - the shovel only gets you so far... WE GOTTA GO IN!!! And here's where me bringing a friend really pays off - he loses the coin toss and goes in:

It's cozy in there:

While he's washing the mash tun, we pulled out and washed the false bottom. Luckily, it's in three pieces and can be handled pretty easily - here's the middle section going back in:

Alright, the mash tun is clean, and we are coming up to a boil:

Measuring out the first addition - 28 oz of Magnum:

The boil was pretty uneventful, with one more hop addition - 40 oz of Fuggles. After the boil was over, we started the whirlpool... That is, Brewmaster Greg grabbed a paddle and stirred the kettle, just like I used to do in my kitchen:

After the whirlpool, we let everything settle for about half hour, and hooked up hoses and configured the heat exchanger to chill the wort to the fermenter:

Hooked up the inline oxygenation system and started filling the fermenter:

With some wort already in the fermenter, we dumped the yeast in (courtesy of Hofbrauhaus brewery in Rosemont, IL):

As the kettle was draining, I was somewhat surprised to see that the ghetto whirlpool actually worked well - check out the nice trub cone:

Well, what's left to do? We take a gravity sample (OG: 19.6 Plato)

They graciously allow me to steal some wort straight from the conical (already pitched with lager yeast), as well as another carboy straight from the wort chiller:

Well, the second carboy needed some yeast, and they needed to dump yeast (Americal Ale II) from their White IPA, so they added a squirt to it:

Oh, the humanity! All this yeast down the drain (they saved a bucket - covered with foil on the left - to pitch into another batch):

Well, all that was left was to clean everything, and put the brewery back the way it was when we arrived:

We were done around 4:30 pm. Not bad for a 300 gallon brew day! We finished the day by sitting at the bar and drinking beer - is there any other way?

This was definitely a once in a lifetime opportunity, and I'm glad to have experienced this! In a few weeks, my beer will be on tap at the brewery, and I have my 10 gallon share sitting in my basement, happily bubbling away.

Cheers!